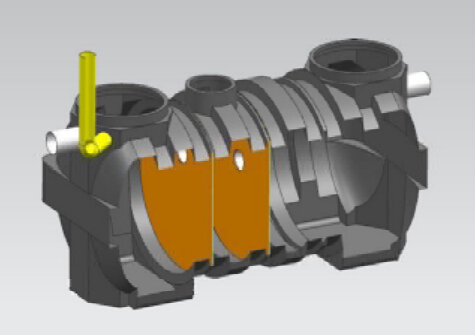

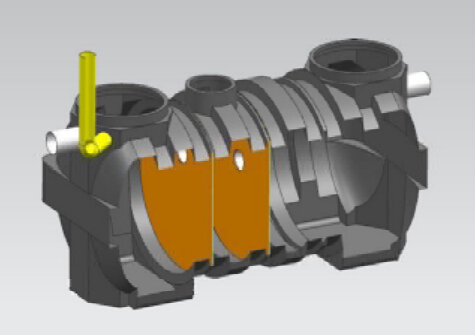

Function of plastic septic tank (1) No leakage. The product uses high strength acid and alkali resistant materials such as high-density polyethylene to form once, good sealing, will not cause fracture damage caused by foundation settlement and the phenomenon of scum layer in the tank, solves the problem of groundwater pollution caused by brick septic tank, and has the function of reliable operation and anaerobic manure.

(2) High compressive strength. The product structure design is reasonable, the pressure is uniform, after more than 200 cycles of testing, the heavy truck on the above rolling does not settle, no deformation.

(2) High compressive strength. The product structure design is reasonable, the pressure is uniform, after more than 200 cycles of testing, the heavy truck on the above rolling does not settle, no deformation.

(3) Small footprint. The area occupied by the product is about 45% of the traditional septic tank, which saves land resources and has the characteristics of flexible site selection.

(4) Convenient installation and construction. It can be installed freely according to the needs of the site, and it can be put into use two hours after installation.

(5) The treatment effect is good. The design of the upper and lower splinter layers of the bulkhead is changed from the original direct flow flooding to circulation flooding, and the matrix transfer is smooth. The application of the anaerobic biological filter (AF) filling system can trap more biomass, and the sewage treatment capacity is more than double that of the traditional septic tank with the same volume.

(6) Long service life. The product is resistant to moisture, acid and alkali, oxidation, high and low temperature without deformation, and the normal service life is more than 50 years.

Plastic septic tank is mainly used in residential communities, office buildings, hotels, schools, hospitals, military barracks, public toilets, people living in concentrated buildings and other places of domestic sewage treatment, food processing enterprises drainage treatment. It can also be appropriately modified to be used as oil-water filter in restaurants, restaurants and other places. (7) Economic use. The overall cost is 80% of the reinforced concrete structure, and it is an environmental protection product promoted by the urban construction department.

(7) Economic use. The overall cost is 80% of the reinforced concrete structure, and it is an environmental protection product promoted by the urban construction department. Plastic septic tank is mainly used in residential communities, office buildings, hotels, schools, hospitals, military barracks, public toilets, people living in concentrated buildings and other places of domestic sewage treatment, food processing enterprises drainage treatment. It can also be appropriately modified to be used as oil-water filter in restaurants, restaurants and other places.

(2) High compressive strength. The product structure design is reasonable, the pressure is uniform, after more than 200 cycles of testing, the heavy truck on the above rolling does not settle, no deformation.

(2) High compressive strength. The product structure design is reasonable, the pressure is uniform, after more than 200 cycles of testing, the heavy truck on the above rolling does not settle, no deformation.

Home

Home

Product

Product

Tel

Tel